Case

Is there an abnormal rejection? First, confirm whether the correct accessory is used for the selection scale.

Have you ever experienced this?

When you change the packaging specifications of a production line from 150g to 50g, or change the packaging bag to a plastic bottle or paper box, the detection efficiency of the checkweigher has fluctuated significantly or abnormal rejection occurs repeatedly At this time, you may adjust the parameters of the packaging machine and checkweigher from the software perspective again, but the effect is often unsatisfactory.

In fact, this situation may not be caused by incorrect parameters of the checkweigher, but because you did not replace an important accessory in time after adjusting the packaging specifications—the checkweigher rejection device.

.

For example, Haichuan Intelligent Checkweigher Series for example, we have blowing, lever, sliding, swing arm four rejection methods to choose from. If you also have "choice difficulty syndrome" and don't know how to choose the appropriate rejection method according to the specific situation, then this article will definitely answer your questions!

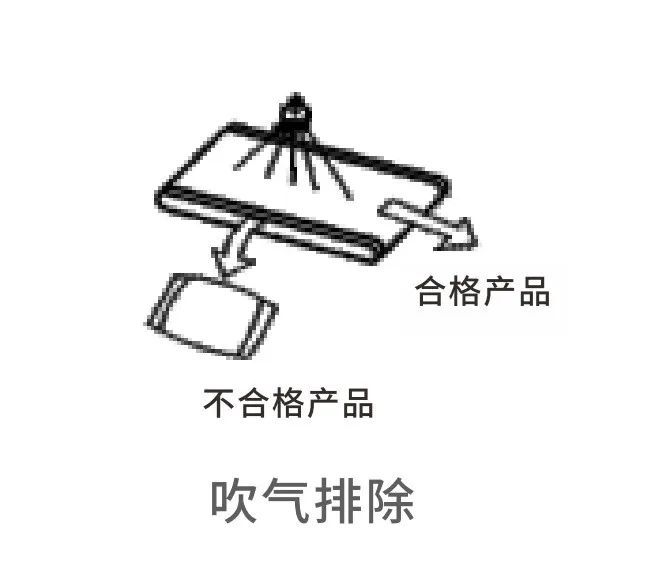

The pneumatic ejector uses compressed air as the air source, controlled by a solenoid valve. Once triggered, the compressed air can be directly blown out at high pressure, and the high-speed airflow generated can remove the product from the conveyor belt.

What occasions are suitable for pneumatic ejection devices? If your packaged product weighs less than 80g, and the spacing between products is short, and rejection requires high speed then pneumatic is definitely your best choice!

Haichuan Intelligent Checkweigher The pneumatic device can achieve accurate rejection at a rate of 100 packs/minute, suitable for medicine packs, tea, small bags of snacks etc. various common scenarios.

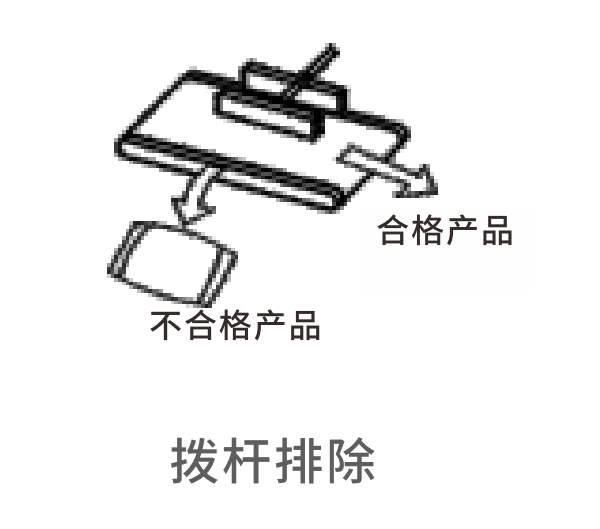

The lever-type ejector is driven by a pneumatic cylinder piston, and the push rod on it is equipped with a rectangular or circular baffle. When the cylinder is driven by compressed air, the baffle will remove the product on the conveyor, and an electric push rod can also be used. However, because the forward and backward movement of the push rod takes time, its rejection speed is slightly slower than the pneumatic type.

However, the lever type is suitable for a wider variety of product packaging sizes , with weights ranging from 0.5KG to 20KG Packaged products are more suitable for using lever type.

Haichuan Intelligent Checkweigher The lever device can remove products from both sides of the conveyor belt, suitable for bread, bottled candy, aquatic products etc.

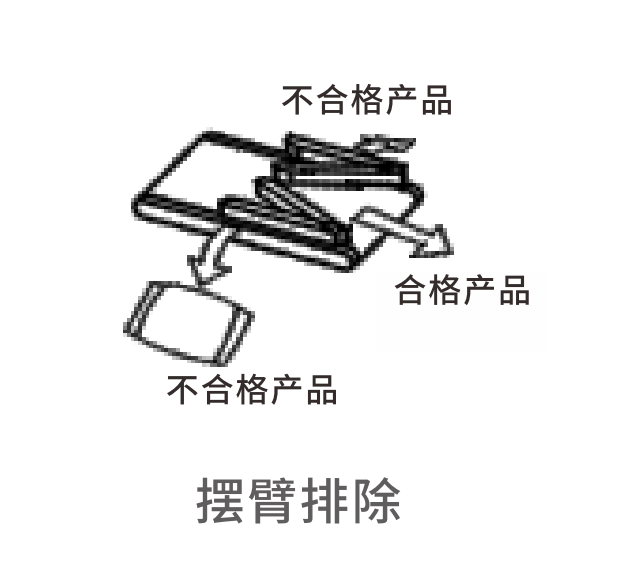

The swing arm type ejection device is suitable for products with a length of more than 100mm and a height of not less than 20mm weight and sorting. The detection and rejection speed is moderate, for example, Haichuan Intelligent Taking the swing arm type ejection device as an example, the speed is about 60 packs per minute, which is a more common ejector.

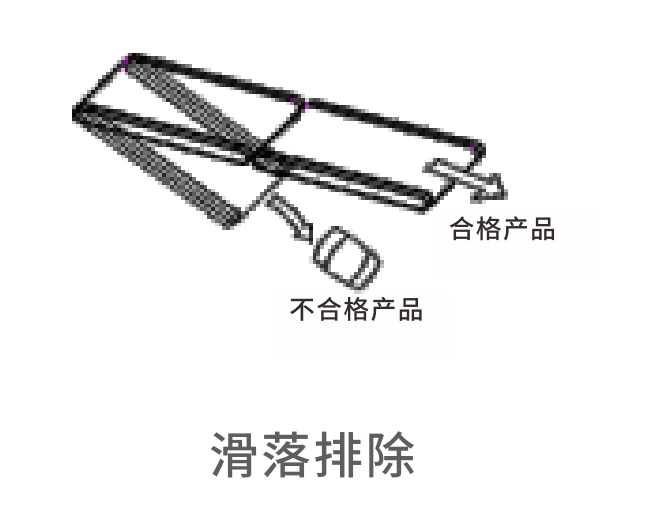

Another sliding type ejection device has a higher speed, but it requires the rejected product to slide down automatically, and there is inevitably a certain height difference, which is generally suitable for products with a height of no more than 50mm 。

The diversification of packaging reflects the current consumer demand and also tests the automated operation and equipment capabilities of manufacturing enterprises. Working with Haichuan Intelligent, whether it is a checkweigher rejection device or other packaging weighing needs, we can provide you with one-on-one professional consultation and testing services to prepare for the challenges of higher precision and speed weighing and detection in the future!

Previous Page

Related Cases